i2S Flawscan

Booth Number:1W05

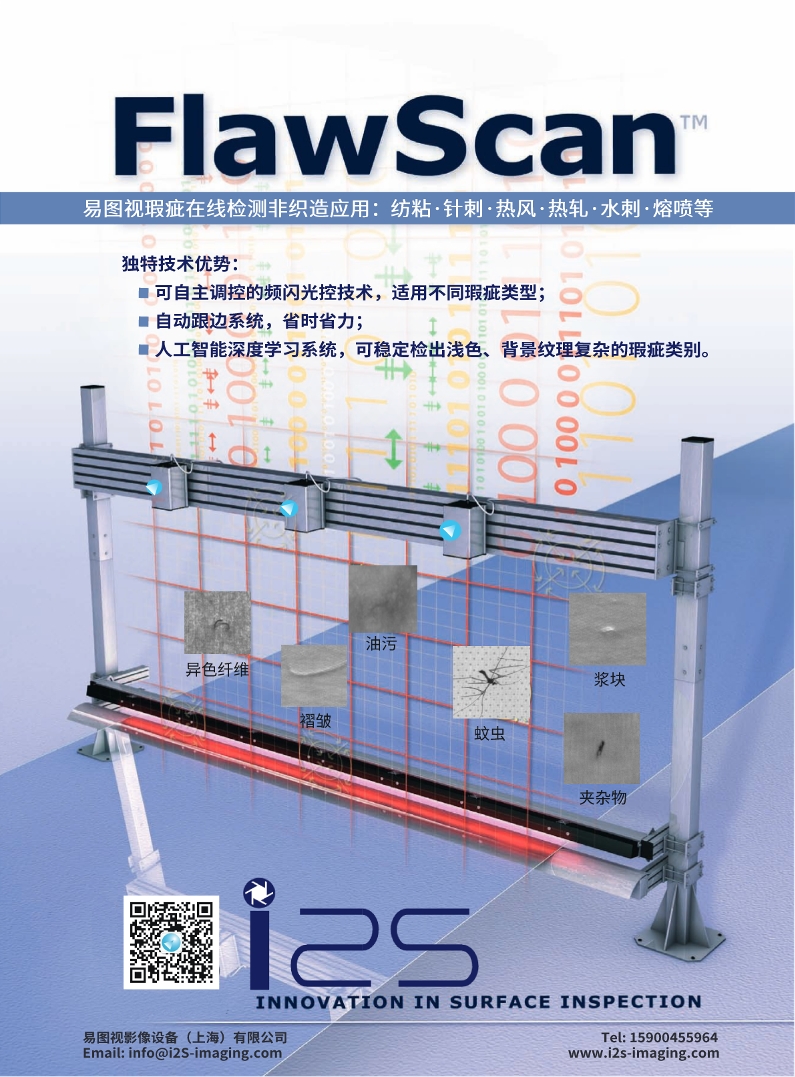

i2S Flawscan aims to provide advanced online surface defect inspection systems for customers in various industries including nonwoven, plastic film/sheet, glass manufacturing, metal manufacturing, paper, and solar energy. The company's FLAWSCAN® online defect detection system performs 100% comprehensive and accurate defect detection for customers, displays defect images, and conducts classification, statistics, and analysis, generating reliable defect positioning and reports. It can also perform real-time labeling according to customer requirements, and offline rewinding for defect picking. This not only gives you a complete understanding of your production process and product quality information, optimizing production process control, but also makes your customers trust and satisfied.

i2S FLAWSCAN provides a complete set of surface defect inspection systems for nonwoven, plastic film, glass manufacturing, metal manufacturing, paper, and solar energy industries:

System Performance:

High-speed cameras and processing technology

Automatic edge detection (no manual setup required)

LED synchronized strobe lighting with low energy consumption and long lifespan

Adaptive lighting brightness for different patterns and fabric thicknesses

Intelligent classification engine for accurate decision-making

Proprietary deep learning algorithms for stable detection of low-contrast defects

User-friendly interface for viewing results and operation

Your Benefits:

100% inspection at different production stages

Real-time defect detection, labeling, classification, and display

Identification of defect causes during production

Product grading to improve quality, yield, and reduce waste

Data processing, statistics, and analysis

Replacement of traditional manual inspection to increase efficiency and reduce costs

Reduction of customer complaints and improved satisfaction

Lighting Technology – Features proprietary strobe LED lighting with temperature control, extended lifespan, and low maintenance costs. Dual-light control technology enables a single camera to capture images from two perspectives, adapting to different product materials and defect types.

Automatic Edge Tracking System – Eliminates manual boundary setup. Detection range remains unaffected by roll changes or product fluctuations, saving time and labor for operators.

AI-Powered Inspection System – Reliably detects subtle defects like light oil stains (low contrast) and surface flaws on complex background materials, ensuring broader application coverage.

Discover More Products!

Visit us at Booth 1W05 during SINCE 2025 (Dec 3-5, 2025) to explore our full range of solutions.

Copyright © 2026 亿百媒会展(上海)有限公司 All Rights Reserved. 沪ICP备13004811号-7 公安机关备案号:31010102004374 隐私政策